At Mack Molding, quality and precision are at the core of what we do—and that starts with metrology. With state-of-the-art equipment, expanded capabilities, and a commitment to advanced training, our team ensures customers receive reliable, validated measurements that meet the highest industry standards.

At Mack Molding, quality and precision are at the core of what we do—and that starts with metrology. With state-of-the-art equipment, expanded capabilities, and a commitment to advanced training, our team ensures customers receive reliable, validated measurements that meet the highest industry standards.

While Mack has made significant investments in new metrology technology and lab space, the most impactful improvement has been in training—ensuring that our inspection techniques remain cutting-edge as customer requirements evolve.

Investing in Training for Consistent, Reliable Measurements

One of the most important developments in Mack’s metrology department is the adoption of AUKOM training, a globally recognized certification program for metrology best practices.

“AUKOM standardizes inspection techniques across different machines, software, and industries,” says Metrology Manager Joe Taylor. “It ensures that no matter where a part is inspected, the measurement process follows proven, internationally accepted methods.”

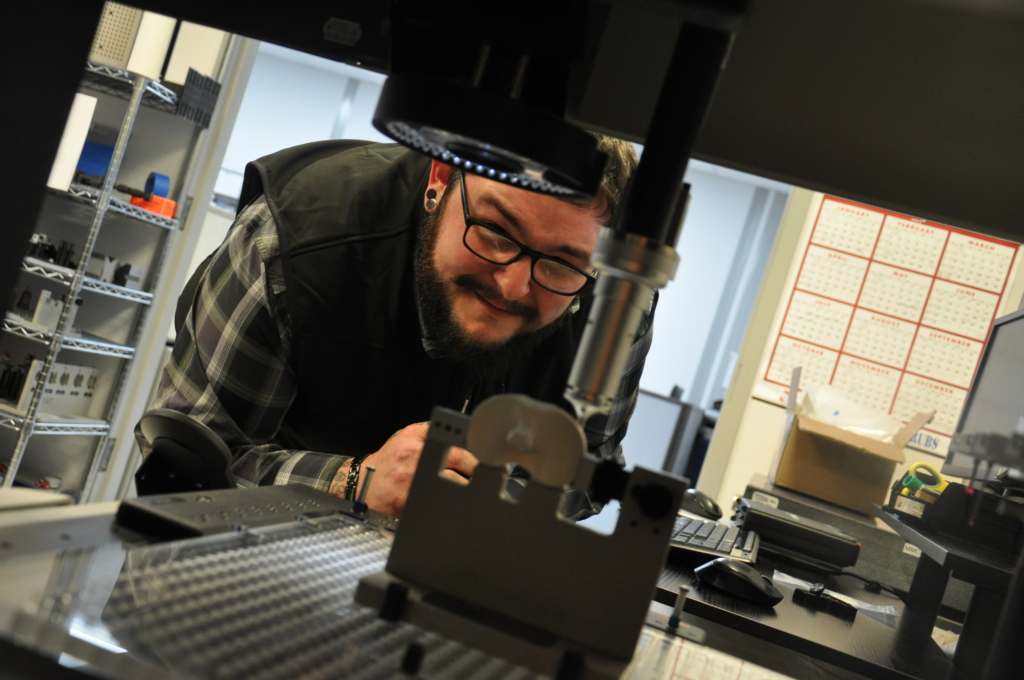

Metrology Applications Engineer Dakota Burdick, a key team member in Mack’s metrology department, took the initiative to pursue AUKOM training, earning certification that strengthens the credibility of Mack’s measurement capabilities.

“Some customers—especially in Europe—won’t even consider a supplier without AUKOM-trained inspectors,” Dakota explains. “It ensures that factors like part cleanliness, temperature, humidity, and environmental conditions are accounted for during inspection.”

For customers, this means:

- Greater confidence that measurements from Mack are accurate and repeatable

- Faster approvals and fewer disputes between Mack’s measurements and a customer’s own inspections

- Higher-quality parts that meet strict industry standards, especially in medical and precision manufacturing

“Customers expect complex dimensional inspections even for simple components,” says Joe. “Twenty-five years ago, you could check mounting positions with a scale or calipers. Now, CMM inspection is the norm, and we have to be prepared to meet those expectations.”

New Technology for Faster, More Comprehensive Metrology Inspections

To support our highly trained metrology team, Mack has also invested in the latest measurement technology, ensuring that our inspections are not only accurate but also efficient.

Two of the most significant upgrades include:

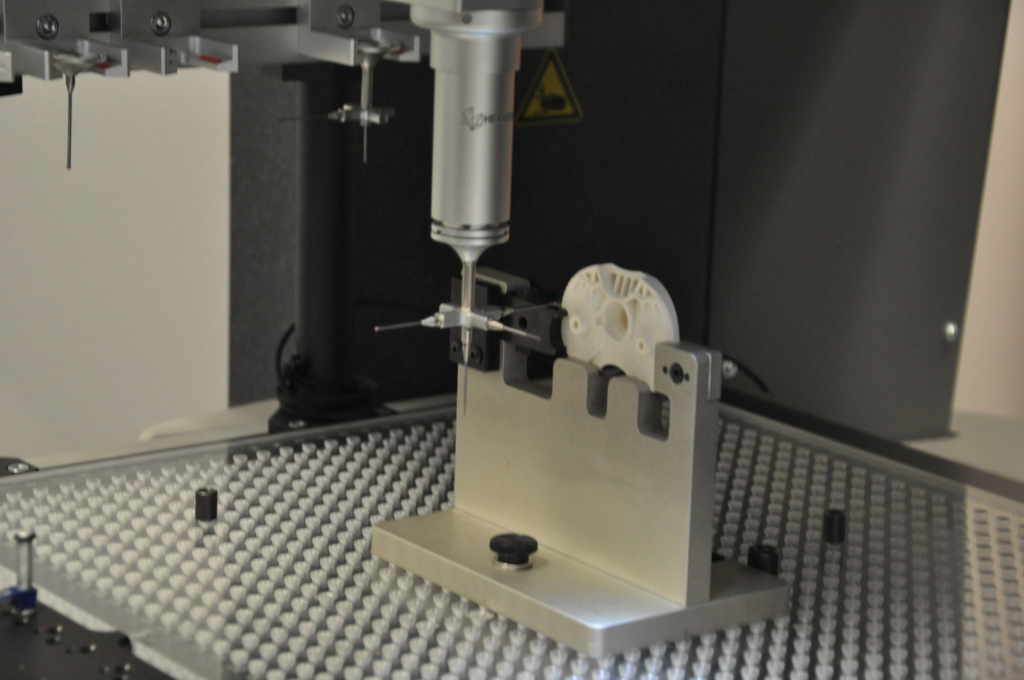

- Hexagon Metrology Global Scan Plus CMM – A next-generation coordinate measuring machine (CMM) with tactile scanning technology. Unlike traditional touch-trigger CMMs, which take individual data points, this system continuously scans, capturing more data in less time for a more detailed and precise inspection.

- Hexagon Optiv Dual Z 443 Vision System – A multi-sensor system that combines contact (CMM) and non-contact (vision-based) measurement, allowing one machine to perform the work of two.

“This technology allows us to inspect parts more efficiently and thoroughly,” says Joe. “A process that used to take 2.5 hours is now done in just 45 minutes.”

For customers, these new systems mean:

- Shorter lead times thanks to faster inspections

- More comprehensive data to verify part quality

- Increased confidence in part consistency and compliance

Streamlining Metrology to Improve Efficiency

In addition to training and technology, Mack has expanded and optimized its metrology lab, doubling its footprint to allow for better workflow and efficiency.

“The extra space allows us to use each piece of equipment for its intended purpose without crowding other areas,” says Tory Peeler, Mack’s Director of Quality. “It also gives us the ability to continue developing and improving our processes.”

Mack has also taken steps to bring critical processes in-house, such as gauge calibration, which was previously outsourced. With the addition of a Pratt & Whitney Super Micrometer, Mack can now calibrate high-accuracy measurement tools internally, eliminating long lead times and keeping production moving.

“Customers rely on us to keep production running smoothly, and metrology plays a key role in that,” says Tory. “By keeping calibration and inspection in-house, we reduce potential delays and ensure we meet customer timelines.”

Why This Matters for Customers

For customers in highly regulated industries like medical and precision manufacturing, metrology is more than just inspection—it’s about trust and reliability.

With AUKOM-certified inspectors, cutting-edge technology, and a streamlined process, Mack provides:

- Faster and more accurate inspections

- Greater consistency in measurement data

- Stronger confidence in part quality

“Metrology plays a critical role in how new customers qualify Mack and how we continue to support long-term business,” says Joe. “By staying at the forefront of technology and training, we’re making sure we continue to meet their expectations—both now and in the future.”

At Mack, investing in metrology is an investment in our customers’ success.