Large-part molding, processing expertise with a wide range of materials, sheet metal fabrication, full-service machining, high-speed overhead painting, value-added assembly and warehousing distribution options are some of the key manufacturing capabilities Mack offers customers in the industrial market sector.

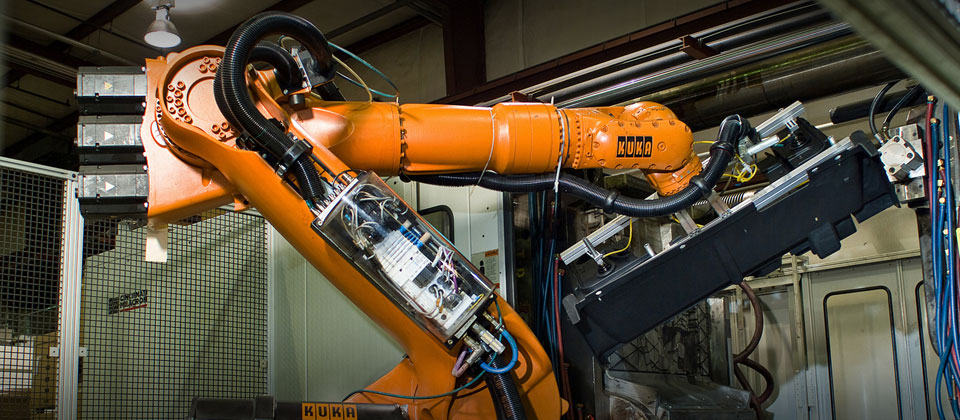

Mack’s automated, conveyorized paint lines are an important element of the manufacturing solution for large-part, high volume applications, such as furniture parts, truck bumpers and large-screen TV cabinets, to mention only a few. Utilizing a wide range of paint systems, Mack can apply all paint up to and including Class A.

Mack’s automated, conveyorized paint lines are an important element of the manufacturing solution for large-part, high volume applications, such as furniture parts, truck bumpers and large-screen TV cabinets, to mention only a few. Utilizing a wide range of paint systems, Mack can apply all paint up to and including Class A.

For many OEM’s, Mack’s 90+ years of processing expertise is a key factor. For the E/One Extreme Series grinder pump, for example, Mack provides insert molding, overmolding with a proprietary TPE blend, and gas-assist molding, which creates a functional channel that acts as a float mechanism for turning the pump on and off.

Finally, Mack offers customized warehousing and distribution solutions, which can be critical in large part manufacturing. From creative stocking arrangements to customer-owned inventory models, Mack can work with you to meet your logistics needs.

Sub-markets

- Material handling

- Power equipment

- Industrial flooring, including ESD (electro-static discharge)

- Sewer systems

- Structural HVAC applications

- Municipal water systems