ENERGY & UTILITIES

Mack Molding

Energy & Utilities: Durable, High-Performance Energy Equipment Contract Manufacturing for Critical Infrastructure

Energy & Utilities: Durable, High-Performance Energy Equipment Contract Manufacturing for Critical Infrastructure

From power generation and storage to waste management and sustainable solutions, the energy and utilities sector demands rugged, reliable, and high-performance components that can withstand harsh environmental conditions. Whether supporting renewable energy systems, grid infrastructure, or water and waste management, Mack Molding provides precision-engineered utility and energy equipment contract manufacturing solutions that drive efficiency, durability, and sustainability.

Powering Renewable & Traditional Energy Markets

Mack Molding supports a broad range of Energy Equipment Contract Manufacturing and utility applications, including:

- Stationary Battery Storage – Over 70 years of experience producing molded, annealed, and tested battery components for auxiliary power solutions for critical sectors like nuclear power plants, hospitals, telecom, data centers and even nuclear submarines

- Renewable Energy Solutions – Components for solar, wind, and alternative energy storage systems

- Grid & Infrastructure Equipment – Housings and enclosures for power distribution and industrial energy management

- Waste & Water Management – Durable, corrosion-resistant components for sewage, filtration, and waste processing systems

- Energy-Efficient Products – Parts for ENERGY STAR® appliances, recycled-content flooring, and sustainable furnishings

Manufacturing for the Future of Energy & Utilities

Manufacturing for the Future of Energy & Utilities

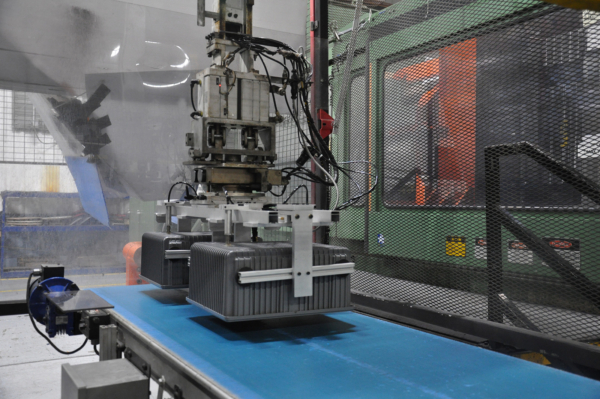

With over 100 years of manufacturing expertise, Mack Molding specializes in high-performance plastic and metal components built for extreme temperatures, corrosion, wear, and chemical exposure. In the 1960s, Mack spearheaded the development of thermoplastic cases, revolutionizing batteries with lightweight, durable containers. Today, our advanced molding and fabrication capabilities continue to ensure long-lasting performance in power, water, waste, and industrial applications.

Advanced Manufacturing Capabilities

- Precision Injection, Structural Foam & Gas-Assist Molding – Strong, lightweight components for high-durability applications

- Overmolding & Two-Shot Molding – Enhanced material properties for sealing, insulation, and corrosion resistance

- Sheet Metal Fabrication & Machining – Custom enclosures, housings, and structural components for industrial and energy systems

- Electromechanical Assembly – Integration of molded parts with PCBs, sensors, and wiring for energy and environmental technology

With 120+ presses ranging from 28 to 4000 tons, we offer scalable production for both emerging innovations and established energy systems.

Sustainability & Environmental Leadership

At Mack, we don’t just manufacture energy-efficient products—we lead by example. We are among the first manufacturers in Vermont to earn the Environmental Leader designation and are ISO 14001 certified for exemplary environmental management practices.

Your Partner in Energy & Utility Innovation

Your Partner in Energy & Utility Innovation

As the demand for energy storage and environmental solutions grows, Mack Molding is well-positioned to support battery manufacturers, renewable energy systems, and sustainable products. Our flexible, integrated manufacturing processes make us the ideal partner for traditional lead-acid battery systems, next-generation energy storage, and alternative energy solutions.

Beyond energy storage, our expertise extends to green products, including recycled-content materials and eco-friendly alternatives. By delivering high-performance, durable, and sustainable components, Mack Molding helps energy and utility companies innovate, optimize performance, and drive sustainability in energy management. We have the engineering expertise, manufacturing scale, and quality systems to support your success.

Let’s build the future of energy together. Contact us today.