Mack Molding, a leading supplier of plastic injection molding and contract manufacturing services, supplies a variety of industries with a unique set of core competencies, including:

- product development resources – part design, prototyping, extensive engineering services and testing

- plastic injection molding – 120 presses from 28 to 4000 tons of clamp force

- large part molding – 33 presses from 1000 to 4000 tons of clamp force

- broad range of finishing operations, including high speed overhead paint lines for high volume, Class A, large part painting

- sheet metal fabrication – metal prototyping and production

- full-service machining

- supply management – product launch purchasing support, quality criteria, key supplier partnerships, component tooling development, engineering changes

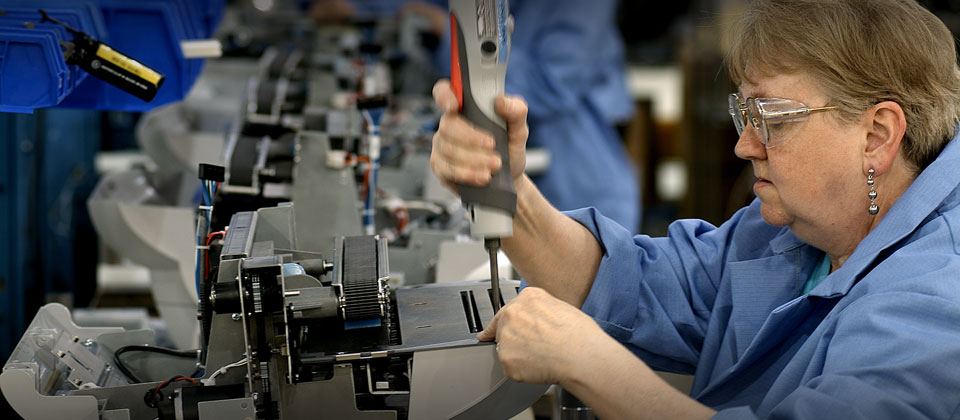

- assembly/contract manufacturing – mechanical, automated and electronic assembly, up to and including total product assembly and ship

- warehousing distribution capabilities – creative inventory stocking arrangements and customer owned inventory models.

Mack’s strategy is to provide a high level of these value-added services to North American manufacturers in the medical, industrial, transportation, energy/environment, computer & business equipment, and consumer markets.

For more details on sub-markets, customers and Mack’s qualifications, please visit the market-specific sections of our site:

Medical | Industrial | Transportation | Energy/Environment |

Computer & Business | Consumer