ARLINGTON, Vt. (Feb. 9, 2016) – Mack Molding, a leading custom plastics molder and supplier of contract manufacturing services, has announced it is working with an Oxford, U.K.- and Boston, Mass.-based laboratory equipment developer that is redefining how research laboratories operate.

ARLINGTON, Vt. (Feb. 9, 2016) – Mack Molding, a leading custom plastics molder and supplier of contract manufacturing services, has announced it is working with an Oxford, U.K.- and Boston, Mass.-based laboratory equipment developer that is redefining how research laboratories operate.

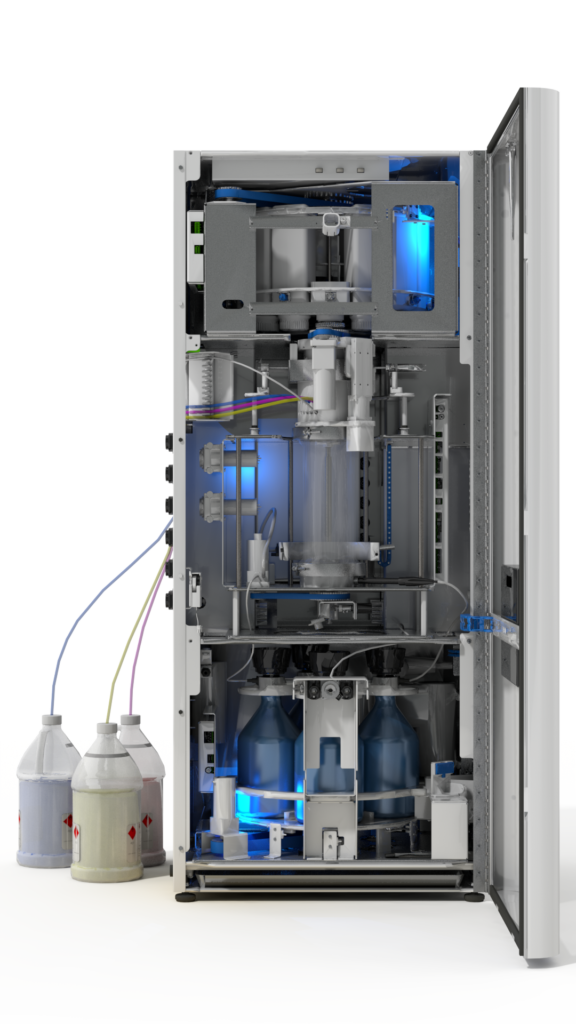

LabMinds’ lead product, Revo, is a smart, adaptable and fully automated liquid solution production system. It offers complete control over measuring and mixing solid and liquid compounds, full process automation and a predictive maintenance approach.

“LabMinds is creating an exciting new market, and Mack is pleased to be part of this emerging frontier in laboratory products,” said Mack Molding President Jeff Somple. “And just as LabMinds releases scientific minds from the burden of procedural lab tasks, we are employing our talents as a full-service contract manufacturer to release them from the burden of building product so they can focus on advancing the technology.”

Born from Oxford University students’ winning entry in a business pitch competition – think Shark Tank – Revo accurately measures and mixes multiple chemicals into a “ready-to-use” solution – the workhorse products of laboratory research. It allows users to order and customize solutions remotely using its web or mobile interface and notifies them when the solutions have been filtered, securely dispensed and are ready to be collected. With its unsurpassed reproducibility and data accessibility, Revo brings a new level of quality control to the laboratory, improving process adherence, efficiency, reproducibility and accuracy while limiting chemical exposure.

The unit stands five-feet tall and measures two feet wide and deep. It has three functioning modules that move on their own, and in total the build includes 560 components. Mack is leveraging its sheet metal shop to provide a significant portion of the components, while the Company’s supplier engineering team sources the additional items. In addition, Mack also is managing final assembly and test of the complete product.

“When we were first introduced to Mack, we launched a top to bottom redesign to better utilize their capabilities – particularly in the area of sheet metal fabrication, which allows for low tooling costs and quick changes,” Michal Wozny, VP Operations, LabMinds. “Mack is now shipping the first production units while continuing to partner with us on design changes focused on ease of use, cost reduction and incorporating feedback from testing, as well as units already placed in the field. Partnering with Mack has not only given us a high-quality manufacturing operation, it has expanded the circle of people with the expertise and passion required to ensure the successful introduction our technology to the marketplace.”

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

About LabMinds

LabMinds develops, manufactures, and sells next generation solutions for laboratory challenges with a particular focus on combining advanced laboratory products with leading edge usability and network technologies. LabMinds’ lead product, Revo, automates the ubiquitous process of solution preparation, combining features such as water purification, solid storage, solid dosing, weighing, stirring, pH control, vacuum filtering, label printing, and GLP adherence in one extremely usable solution.

# # #

Contact: Larry Hovish

(802) 375-0772

larry.hovish@mack.com