LARGE PART PLASTIC MOLDING

Mack Molding – Large-Part & High-Tonnage Molding Services

East Coast expertise in bringing big, complex parts to life with strength, reliability, and cosmetic quality

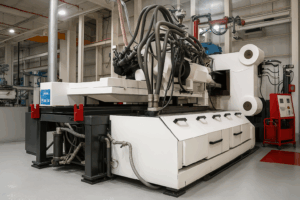

World-Class Large Tonnage Fleet

Our investment in state-of-the-art technology allows us to mold very large, highly complex parts with integrated features that reduce secondary operations.

Southern Large Press Fleet (Inman, SC)

1500T (x5) – 362–540 oz, four presses with 6-axis robots for insert molding & complex part handling

1500T (x5) – 362–540 oz, four presses with 6-axis robots for insert molding & complex part handling- 2000T (x1) – 540 oz, 6-axis side-entry robot

- 2500T (x1) – 470 oz, 6-axis cartesian robot

- 2600T (x3) – 540 oz, end-deposit cartesian, 7-axis overhead rail (150kg), pedestal 6-axis

- 3000T (x1) – 470 oz, 6-axis cartesian robot

- 3300T (x1) – 540 oz, 6-axis cartesian robot

- 4000T (x1) – 769 oz, 7-axis overhead rail robot (210kg)

Northern Fleet Additions (Arlington & Cavendish, VT)

While our Carolinas footprint leads the way in large part molding, Mack also maintains significant large press capacity in Vermont:

- Arlington: 1650T (x2), 1500T (x2)

- Cavendish: 2300T (x1)

Design & Performance Advantages of Large Part Plastic Molding

- Strength & Durability – Molded-in features replace machining or bonding, with parts engineered for demanding environments

- Size Capability – Ability to mold parts up to 5 feet x 3 feet and weighing up to 50 lbs’

- Weight Reduction – Replace metal or fiberglass with plastics and structural foam to cut part weight while maintaining performance

- Design Flexibility – Larger, more complex parts = fewer assemblies

- Cost Savings – Automation and cycle-time improvements deliver volume efficiency

Sustainability & Environmental Stewardship

Mack is committed to delivering large, complex parts with a smaller environmental footprint. Through both technology investments and certified best practices, we ensure that sustainability is embedded in our operations.

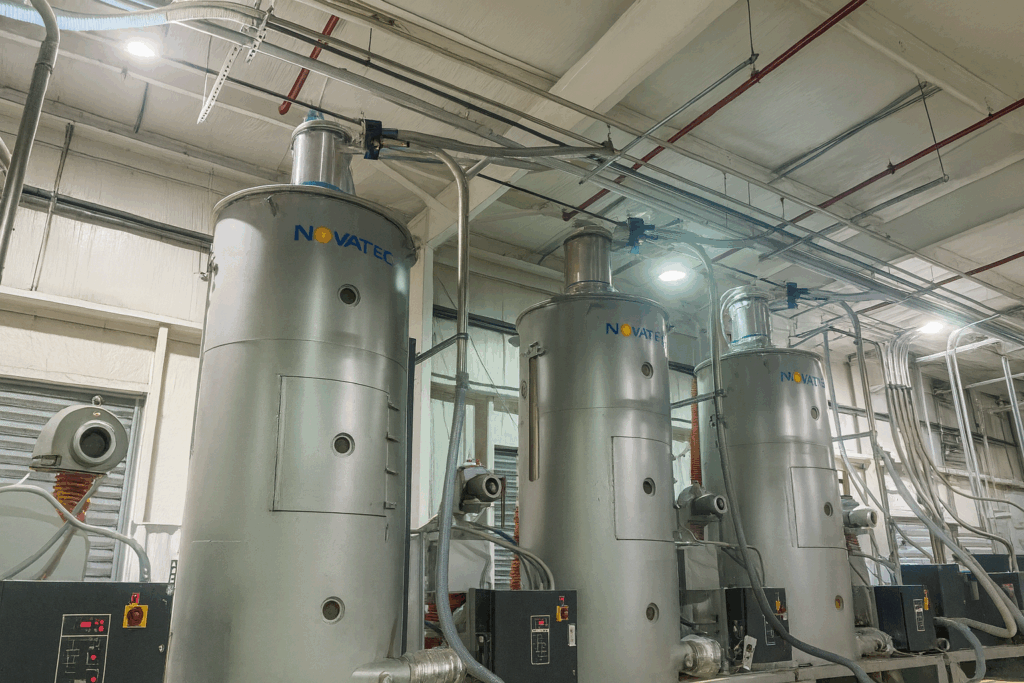

Technology Investments for Efficiency

We’ve made significant system upgrades to improve energy efficiency and consistency in large-part molding:

We’ve made significant system upgrades to improve energy efficiency and consistency in large-part molding:

- Nine servo-hydraulic presses (Inman) → 20% lower energy use’

- Five all-electric & seven servo-hydraulic presses (Statesville)

- Central drying system: 3,000 lb/hr capacity, closed-loop conveyance

- Bulk resin storage: three 120,000 lb silos for reduced handling and waste

Certified Environmental Management

Mack’s Southern Division has maintained ISO 14001 certification since 2007 — an internationally recognized standard for environmental management systems. This certification underscores our commitment to sustainable manufacturing and continuous improvement. Our North and South Carolina facilities implement comprehensive environmental controls, including:

- Pellet Loss Prevention Plan

- Comprehensive Environmental Policy Manual

- Stormwater Pollution Prevention Plans

- Hazardous & Non-Hazardous Waste Management Plans

- Integrated Environmental, Health & Safety (EHS) incident reporting system

Each facility is staffed by a full-time EHS manager and undergoes biannual environmental reviews to ensure measurable progress toward sustainability goals.

Advanced Capabilities

From molding to finishing, Mack brings advanced technology to every step:

- Gas Assist Molding – Seven 4-zone controllers (up to 4,500 psi)

- Automation – 6- and 7-axis articulating arm robots increase flexibility for inserts, pick-and-place, and complex part removal

- Post-Mold Services – Robotic degating, in-house CNC machining, custom fixturing

- Engineering Support – On-site experts handling mold design and automation

Markets We Serve

Our large press fleet supports demanding industries where scale and durability matter:

- Heavy Truck & Transportation

- Lawn, Garden & Recreational Vehicles

- Agricultural Equipment

- Medical Device Skins & Enclosures

- Energy & Utility Enclosures

Strategic Locations to Serve Our Customers

Mack Molding provides custom plastic injection molding and contract manufacturing services through a vertically integrated network of facilities in the Northeast and Southeast U.S.:

- Southeast (North Carolina & South Carolina): Easy access to Georgia, Tennessee, Virginia, Florida, and Alabama, including major medical, industrial, and transportation hubs.

- Northeast (Vermont): Strategic New England location with reach into Massachusetts, New Hampshire, Connecticut, New York, and Pennsylvania — home to leading medical, industrial, robotics, and energy/utility markets.

By combining regional accessibility with world-class large press technology, Mack delivers precision molding, complex assemblies, and large-part production where customers need them most.

Your Advantage

With Mack, you get a highly automated, energy-efficient fleet designed for large, complex, cosmetic-critical parts. Our advanced capabilities — from servo-hydraulic and all-electric presses to gas-assist molding, robotic handling, and in-house CNC machining — reduce waste, improve consistency, and cut cycle times. And with a dual footprint — New England for the Northeast, Carolinas for the Southeast — Mack combines regional reach and vertical integration to deliver confidence in every part.