CONTRACT MANUFACTURING

Mack Molding – Full-Service Contract Manufacturing & Product Assembly

Integrated manufacturing solutions that take your products from concept to market

Integrated manufacturing solutions that take your products from concept to market

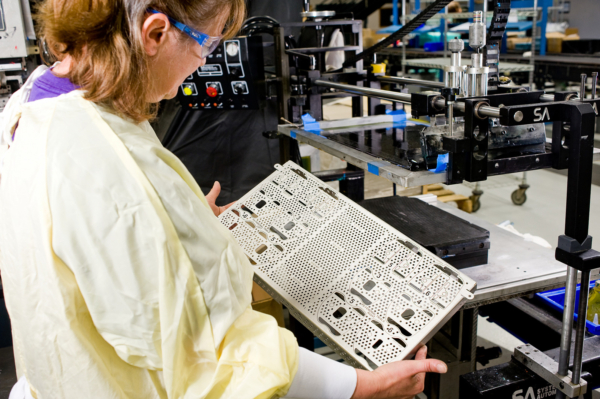

Mack Molding has evolved from a custom injection molder into providing a full range of contract manufacturing services with deep expertise in complex mechanical and electronic assemblies, including Class III PMA medical devices. Our vertically integrated services provide a single-source solution that reduces risk, eliminates handoffs, and accelerates your product’s time to market.

Whether you need complete contract manufacturing services or select services to fill gaps in your supply chain, Mack Molding offers the flexibility to adapt to your needs.

Your Contract Manufacturing Partner

Mack Molding operates as an extension of your manufacturing team, offering a fully integrated approach that flows seamlessly from design & development to final product assembly and distribution. Our capabilities include:

- Product Design & Development – Optimize manufacturability, functionality, and cost.

- Rapid Prototyping – Accelerate design iterations and testing with 3D printing, CNC machining, and low-volume molding.

- Tooling – Ensure high-quality part production with precision-engineered mold tools. We collaborate closely with toolmakers to optimize tool design, material selection, and production efficiency.

- Custom Injection Molding – Advanced plastics manufacturing, including gas-assist molding.

- Sheet metal fabrication & full-service machining – Precision manufacturing for structural components.

- Component Sourcing & Supplier Management – Robust procurement for quality and cost control.

- Sub-Assembly & Full Product Assembly – Mechanical and electronic integration.

- Testing & Quality Assurance – Ensuring performance, compliance, and reliability.

- Global Distribution & Logistics – Direct shipping to you, your distributors, or third parties.

Enhancing Efficiency with Digital Manufacturing Software

Enhancing Efficiency with Digital Manufacturing Software

At Mack Molding, we leverage advanced digital manufacturing software to enhance our operational efficiency and product quality. This platform connects our workforce, machinery, and IT systems, providing real-time insights into our manufacturing processes. By utilizing interactive, digital work instructions, we improve operator training and productivity, moving beyond traditional paper-based methods. The system also enables our engineers to develop custom applications that validate data entry, monitor key performance indicators, track cycle times, and maintain calibration schedules. This integration of industrial IoT and real-time analytics ensures rapid issue identification and resolution, facilitating continuous improvement and seamless data sharing with our customers.

Contract Manufacturing Tailored to Your Needs

Mack Molding’s modular approach allows you to engage in a full contact manufacturing services partnership or select only the services you need. Whether it’s prototype-to-production or simply contract assembly, our team ensures a streamlined, cost-effective process designed around your specific requirements.

Precision Assembly & Secondary Operations

Mack Molding provides mechanical and electronic assembly services across multiple facilities, with extensive secondary operations for finishing, decorating, and painting.

- Decorating & Finishing

- Heat sealing, heat transferring, and hot stamping

- Pad printing for custom branding

- Decorative and conductive painting, including EMI/RFI shielding

- Advanced Painting Capabilities

- Five high-volume, automated paint lines

- Paint robots for precision and consistency

- Class A, soft-touch, and metallic finishes

- In-house priming for seamless color coatings

- Custom masking solutions for high-volume production

Business Unit Model: A Dedicated Team for Your Project

Every Mack Molding customer is assigned a dedicated business unit, ensuring streamlined communication and engineering-intensive program management. Under the leadership of a Business Unit Director, your team includes experts in:

- Engineering & Design Support

- Prototyping & Test Development

- Supplier & Quality Management

- Manufacturing Optimization

This customer-focused approach reduces response times, increases flexibility, and improves technical support, making Mack Molding feel like a small, responsive partner—despite our large-scale capabilities.

Contract Manufacturing & Production Management

Contract Manufacturing & Production Management

Mack Molding’s manufacturing process is designed for:

- Cost & Time Efficiency – Optimizing layouts, materials, and workflows

- Ergonomics – Creating safe, efficient production environments

- Quality Assurance – Built-in mistake-proofing and statistical quality control

From early manufacturability reviews to final product testing, our team ensures scalability, reliability, and compliance throughout the production cycle.

Distribution & Supply Chain Management

As a global logistics partner, Mack Molding ensures on-time, cost-efficient delivery through:

- Inventory & Demand Planning – Optimizing stock levels and reducing waste

- Direct-to-Consumer, Warehouse, or 3PL Shipping – Custom fulfillment options

- 94,000 sq. ft. Distribution Center with 19 Loading Docks – Scalable logistics for global markets

Our logistics team continuously monitors freight costs and performance metrics to deliver the best shipping solutions for our customers.

Supplier Management & Cost Control

Supplier Management & Cost Control

Mack Molding’s procurement team operates through commodity-based supplier partnerships to ensure:

- New Product Introduction (NPI) Support

- Cost-Effective Component Sourcing

- Quality-Driven Supplier Qualification

- End-to-End Supply Chain Transparency

All suppliers undergo a rigorous qualification process, including site audits, first article inspections, process validation, and quality documentation reviews.

Contract Manufacturing Expertise in the Northeast and Southeast U.S.

With operations in both New England and the Southeast, Mack’s contract manufacturing services are within easy reach of major OEM hubs. Our Vermont facility provides convenient access to Massachusetts, New Hampshire, Connecticut, New York, and Pennsylvania, while our North Carolina and South Carolina facilities extend coverage into Georgia, Tennessee, Virginia, Florida, and Alabama.

Case Studies: Real-World Success

Automated Self-Serve Blender

Challenge: Develop a fully automated, self-cleaning blending system with integrated remote diagnostics and digital marketing capabilities.

Mack Molding’s Role: Full contract manufacturing, including plastics and sheet metal fabrication, assembly, supplier management, and logistics.

RFID-Enabled Inventory Management System

Challenge: Create a medical inventory management system with RFID tracking for real-time usage monitoring and supply chain optimization.

Mack Molding’s Role: Custom fabrication of RFID-enabled cabinets, electrical assembly, and ISO-certified quality control for seamless integration.

Solar-Powered Waste Management System

Challenge: Develop a durable, solar-powered waste solution designed to minimize collection costs and reduce environmental impact.

Mack Molding’s Role: Injection molding, sheet metal fabrication, full product assembly, and international logistics support for scalable deployment.

Why Mack Molding?

Why Mack Molding?

Mack Molding’s vertically integrated contract manufacturing provides:

- A single-source solution – reducing risks and streamlining production.

- Scalability – from prototype to high-volume production.

- Engineering-Driven Program Management – expert support from design through distribution.

- End-to-End Accountability – one trusted partner for the entire manufacturing process.

Let’s Build Something Together

Whether you need a full contract manufacturing partner or targeted production services, Mack Molding delivers the expertise, scale, and agility to bring your product to market—faster and more efficiently.

Get in touch today to discuss your project needs and see how Mack Molding can drive your success.