Company Mobilizes Resources & Personnel to Maintain Competitive Advantage

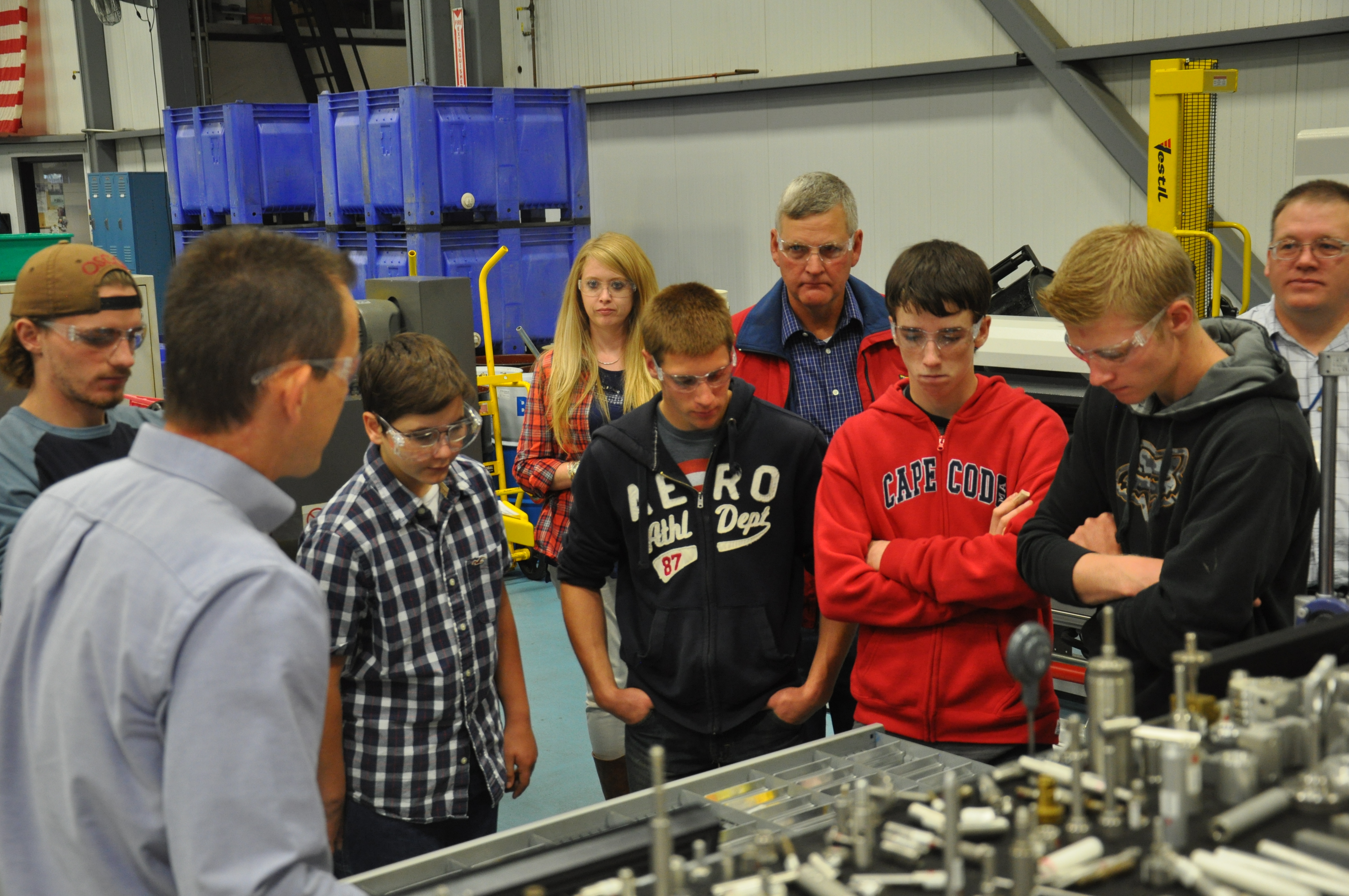

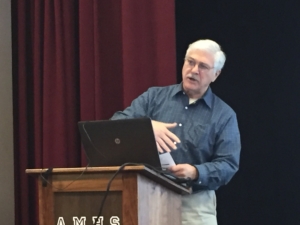

Mack Regulatory Compliance Manager Lee Fox discusses the new revisions to ISO 9001 and ISO 13485 and the Company’s implementation plans during an offsite mobilization event Jan. 24, 2018, at the Mack Performance center at Arlington High School.

ARLINGTON, Vt. (Feb. 6, 2018) – Mack Molding, a leading custom plastics molder and supplier of contract manufacturing services, is in the midst of systematizing ISO 9001:2015 and ISO 13485:2016 – the fifth and third revisions, respectively, of the international standards for general quality management and assurance, as well as for medical devices.

Mack’s ISO certifications are critical to not only assuring its customers their products will meet expectations, but also in the Company’s business continuity. More than 140 members of its manufacturing, quality, sales, engineering and leadership teams recently gathered for an in-depth discussion on what the new standards mean for Mack and how they will be implemented. Next Mack will train internal auditors to help ensure it is ready to become certified following audits scheduled to take place in July.

“When we first implemented ISO 9001 in 1990 we were one of a handful of injection molders to do so,” said Mack Molding President Jeff Somple. “It was a great selling point at the time, but today it is a necessity – a license to do business in the highly technical markets we serve. In the early 2000s we implemented ISO 13485 to gain access to the medical device industry, and as a result today we are a stronger, more diverse organization. It has proven to be a competitive advantage for Mack, and the good news is we are already doing most of what the new standards require.”

Mack personnel were briefed on the new revisions to ISO 9001 and ISO 13485 and the Company’s implementation plans during an offsite mobilization event Jan. 24, 2018, at the Mack Performance center at Arlington High School.

A significant piece of the new standards is based on risk management and ensuring employees are aligned with organizational goals. This ties in neatly with Mack’s existing strategy for growth. Known internally as the Seven Key Success factors, the Company uses intelligent business growth, total customer satisfaction, employee satisfaction, profitability, competitive readiness, risk management and environmental sustainability as its guiding principles.

“We are well on our way to achieving what ISO, and many of our customers, are looking for,” Somple added. “It goes far beyond what most organizations would consider for a quality management system, emphasizing the management piece in ways that have already proven to be our strength. Risk-based thinking is a critical part of engineering, however, we cannot rest on our laurels. That is why Mack is committing the resources and the time to get it right.”

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

###