Tulip Connects Workers, Machines & IT Systems to Provide Real-Time Insight into Operations

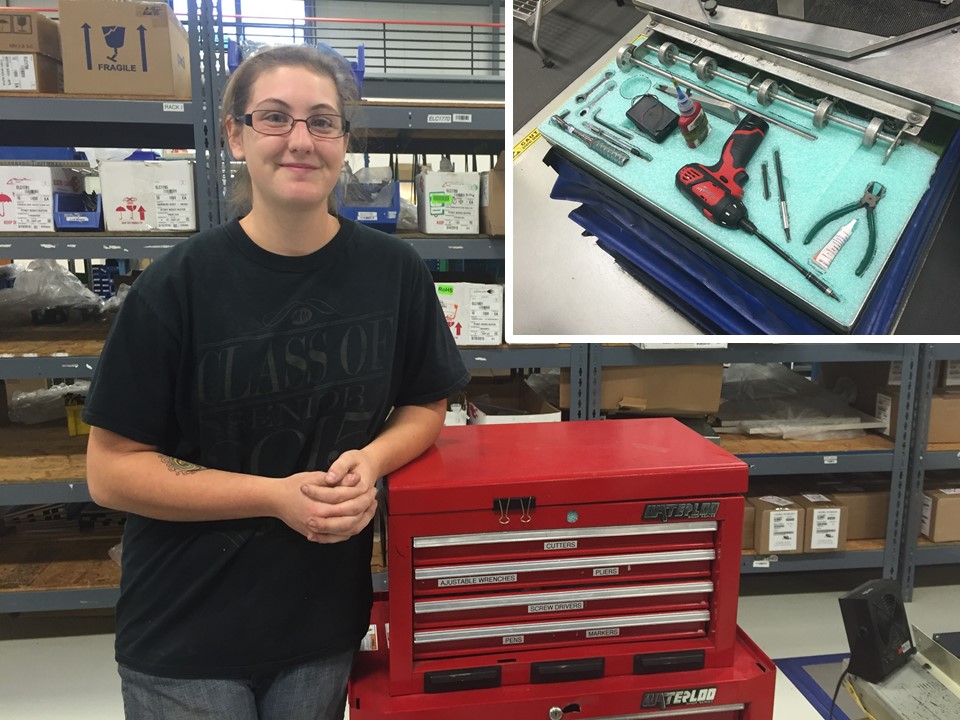

ARLINGTON, Vt. (Feb. 5, 2019) – Mack Molding has announced it has expanded its relationship with Tulip, the manufacturing App Platform. Tulip’s cloud-based platform augments the productivity of Mack’s workforce with shop-floor apps, industrial IoT and real-time analytics.

“It is similar to a manufacturing execution system, only better,” said Headquarters Plant Manager Rich Hornby. “With big pictures, interactive elements and videos it is more efficient than paper-based work instructions when training new operators. Real-time data allows our team to rapidly recall information, ensuring we don’t find out tomorrow there was a problem today. Tulip also provides us with a platform to easily share data with our customers as they are just a click away.”

“It is similar to a manufacturing execution system, only better,” said Headquarters Plant Manager Rich Hornby. “With big pictures, interactive elements and videos it is more efficient than paper-based work instructions when training new operators. Real-time data allows our team to rapidly recall information, ensuring we don’t find out tomorrow there was a problem today. Tulip also provides us with a platform to easily share data with our customers as they are just a click away.”

Mack has been testing Tulip at its headquarters for approximately a year, and will now begin rolling out the digital factory management software throughout the facility. The program allows Mack’s manufacturing and quality engineers to build apps on their own, enabling better operator training and increased productivity through guided, interactive work instructions. In addition, the apps validate data on entry, record KPIs, cycle-time data, collect critical data for customer traceability and track gauges, calibrations and due dates, all in real-time.

“It is highly customizable,” Hornby noted. “We like to say it is open to what your imagination can handle. Most importantly it puts the power of information, and the ability to act on it, into the hands of our front-line engineers, supervisors and operators. This gives them the ability to drive productivity and direct continuous improvement efforts.”

“We’re thrilled about this expansion with Mack,” added Tulip’s Head of Customer Operations Erik Mirandette. “We’re excited to see how they continue innovating with manufacturing apps and leading the way in their space.”

About Tulip

Tulip, the Manufacturing App Platform, is being used by leading manufacturers around the world to increase the productivity, quality and efficiency of their operations. Launched out of MIT, the company is headquartered in Somerville, Mass., with offices in the UK and Germany. It has been recognized as a Gartner Cool Vendor, IDC Innovator, Frost and Sullivan Entrepreneurial Company of the year, an AWS Partner Network member and a World Economic Forum Technology Pioneer. Learn more at Tulip.co.

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

# # #