COMPANY SEES CROP OF FORMER INTERNS RETURN AS FULL-TIME EMPLOYEES

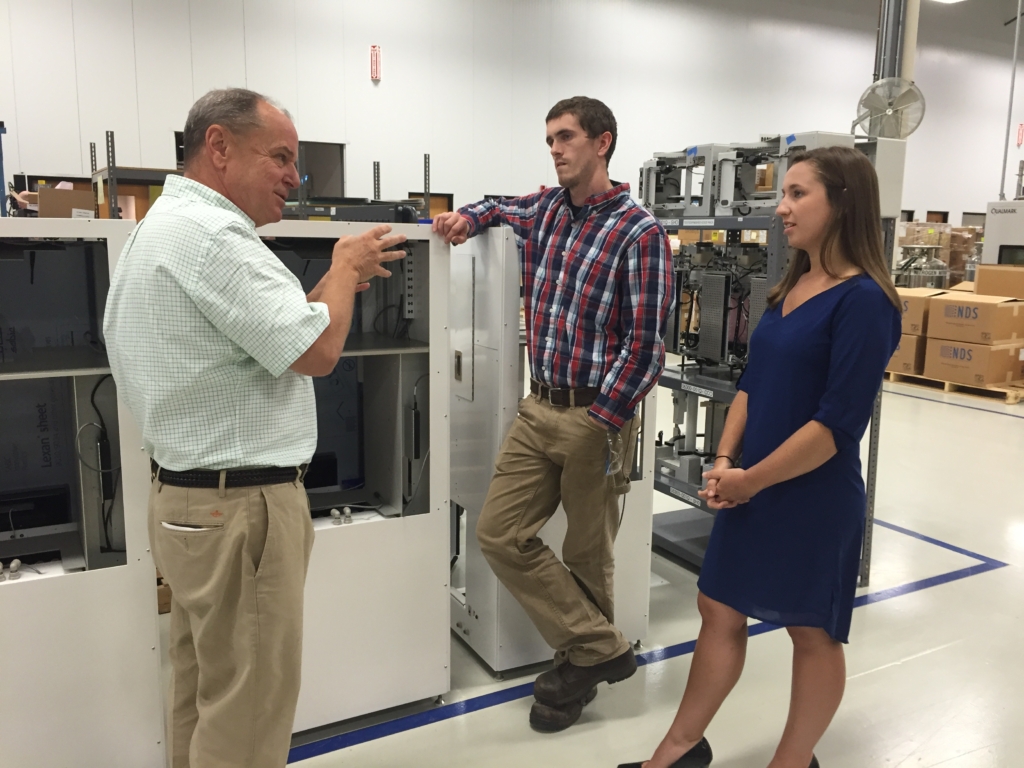

From left, clockwise, Mack Molding President Jeff Somple discusses one of the Company’s new programs with Finishing Technician Matt Comar and Program Coordinator Britney Coley. Comar and Coley are former interns who have recently returned to Mack as full-time employees.

ARLINGTON, Vt. (June. 14, 2016) – Mack Molding, a leading custom plastics molder and supplier of contract manufacturing services, announced today three former interns are returning to the Company as full-time employees, highlighting its outreach efforts to cultivate the next generation of talent needed to drive manufacturing in the Northeastern United States.

St. Lawrence University graduate Britney Coley has joined Mack as a program coordinator along with Hudson Valley Community College’s Matt Comar, who has returned to Mack as a finishing technician. Additionally, Peter Bush, a recent graduate of the University of Vermont, will be joining the team as a quality engineer.

“It is with great excitement and pride that we welcome these three talented young professionals back to Mack,” said Mack Molding President Jeff Somple. “During the last several years we have put significant effort into building a sustainable workforce by encouraging the next generation of engineers, technicians and professionals. It is important not only as a manufacturer, but as a Vermont business, to show students just how rewarding a career in manufacturing – and a life in Vermont – can be. We have started with children as young as kindergarten, through high school and of course our internship program and today, as sure as salmon returning to their home stream, we know our work to establish a sustainable workforce is paying off.”

For Coley, whose father works as a manufacturing engineer at Mack’s East Arlington facility, Mack is in her blood, even if she did not originally intend to enter the family business.

“It really started because my father worked here,” she explained, “but the more time I spent at Mack the more I grew to love it. With a bachelor of science degree in biology and psychology my original notion was to get into medicine, but through my experience at Mack I had an epiphany that medical devices represented a good mix for me – allowing me to merge my passions for manufacturing and medicine.”

As a program coordinator in the Company’s growing medical device sector, Coley works with cutting edge technology. She helps maintain program schedules and records, facilitates document control tasks and interface with customers as part of a multi-disciplinary team from across the organization focused on launching new products, improving performance and ultimately achieving Mack’s mission of Total Customer Satisfaction. During her time as a Mack intern, Coley worked for both the compliance, and sales and engineering, departments, developing a keen understanding for Mack’s processes, as well as customer requirements and exposure to U.S. Food and Drug Administration standards. A member of St. Lawrence University’s Class of 2016, Coley also was an accomplished student, studying abroad in Denmark to gain a better understanding of the global healthcare market. She also served as secretary for the National Panhellenic Conference and was career and personnel director for the Epsilon Kappa Chapter of the Chi Omega Fraternity.

Comar, who studied advanced manufacturing at Hudson Valley Community College has been interning at Mack since May 2015. A graduate of Mount Anthony Union High School in Bennington, Vt., he also gained experience at Loomis Auto in Bennington. He brings experience in Solidworks and Mastercam software, as well as knowledge of CNC mills, lathes and manual machine tools. As a finishing technician, Comar will perform set-ups of various processes, including pad printing, milling and sonic welding, as well as maintain and troubleshoot equipment to maximize efficiency and quality of production.

As a quality engineer, Bush will be ensuring Mack’s work meets the high demands of its customers, supporting operations from new business development through product launches and realization all the way through program end of life. Previously a sales and engineering intern at Mack, he has experience in planning, preparing and organizing resources for class 3 medical device product development studies and facilitating related communication between manufacturing, quality and management.

As a quality engineer, Bush will be ensuring Mack’s work meets the high demands of its customers, supporting operations from new business development through product launches and realization all the way through program end of life. Previously a sales and engineering intern at Mack, he has experience in planning, preparing and organizing resources for class 3 medical device product development studies and facilitating related communication between manufacturing, quality and management.

To date, Mack has hosted close to 100 interns from schools like UVM, WPI, RPI and RIT. While a few have previously returned to take on full-time positions, the Class of 2016 represents the largest group to date to formally bring their careers to the Company.

“We are hosting another 18 interns this summer,” Somple said, “and as with Britney, Matt and Peter, we can only hope to be a positive influence on their pathway to becoming young professionals in their own right, and hopefully illustrating the exciting opportunities available to them in our region and industry.”

Additional New Hires

Mack also is pleased to announce the following additions to its team.

The Mack Headquarters in Arlington, Vt., has welcomed Chris Donza to the IT team as a systems administrator. Donza is responsible for installing and maintaining new and existing hardware, software, storage and other systems to ensure their integrity and continuous access. He brings an extensive background in network administration having previously served as IT technician for the Bennington School District in Bennington, Vt. He is CompTIA A+ certified and gained previous technical experience as a freelance RF technician, as well as with Wild Oats Food Market in Williamstown, Mass., and Rainbow Network Communications in Bethpage, N.Y.

Tom Jackson has joined the manufacturing engineering team at Mack’s headquarters in Arlington, Vt, as a manufacturing engineer. Jackson has a bachelor of science degree in mechanical engineering and a minor in mathematics from the University of Vermont in Burlington, Vt. Jackson is responsible for manufacturing engineering requirements related to an important new disposable medical device kit production. He most recently worked at Keurig Green Mountain in Waterbury, Vt., in design and project engineering.

Tom Jackson has joined the manufacturing engineering team at Mack’s headquarters in Arlington, Vt, as a manufacturing engineer. Jackson has a bachelor of science degree in mechanical engineering and a minor in mathematics from the University of Vermont in Burlington, Vt. Jackson is responsible for manufacturing engineering requirements related to an important new disposable medical device kit production. He most recently worked at Keurig Green Mountain in Waterbury, Vt., in design and project engineering.

Simon Leavitt has joined Mack’s Cavendish, Vt., facility, as a manufacturing engineer providing manufacturing engineering support for a number of customer programs, including the introduction of new/re-engineered products. Leavitt is returning to Mack after having previously served as quality engineer at Mack’s Headquarters in Arlington, Vt. Besides an intimate knowledge of Mack, he brings extensive product development and engineering experience from working with Bob White Systems Inc. and ReKnew Energy Systems, both of South Royalton, Vt. A graduate of Rose-Hulman Institute of Technology in Terre Haute, Ind., Leavitt has a degree in mechanical engineering.

Simon Leavitt has joined Mack’s Cavendish, Vt., facility, as a manufacturing engineer providing manufacturing engineering support for a number of customer programs, including the introduction of new/re-engineered products. Leavitt is returning to Mack after having previously served as quality engineer at Mack’s Headquarters in Arlington, Vt. Besides an intimate knowledge of Mack, he brings extensive product development and engineering experience from working with Bob White Systems Inc. and ReKnew Energy Systems, both of South Royalton, Vt. A graduate of Rose-Hulman Institute of Technology in Terre Haute, Ind., Leavitt has a degree in mechanical engineering.

The Mack Headquarters in Arlington, Vt., welcomes Richard Turner to the team as a manufacturing engineer in the Company’s growing medical device business. Turner, who brings more than 25 years of engineering and manufacturing systems experience, will be responsible for combining an analytical approach with creative thinking to shepherd programs from concept through prototyping and clinical evaluations to phase in and ramp up – ensuring good initial design will be complimented by the ability to replicate it at scale. Prior to Mack, Turner served as a manufacturing engineer supervisor/industrial engineer, and more recently manufacturing engineering manager, for Plasan North America in Bennington, Vt. During his career, he also built his skill set at NSK Steering Systems America in Bennington, Vt.; as well as at J.S. McNamara and Utica Engineering Company in Shelby Township, Mich. Turner has a bachelor of science in engineering degree with a focus on mechanical engineering from Oakland University in Rochester, Michigan.

The Mack Headquarters in Arlington, Vt., welcomes Richard Turner to the team as a manufacturing engineer in the Company’s growing medical device business. Turner, who brings more than 25 years of engineering and manufacturing systems experience, will be responsible for combining an analytical approach with creative thinking to shepherd programs from concept through prototyping and clinical evaluations to phase in and ramp up – ensuring good initial design will be complimented by the ability to replicate it at scale. Prior to Mack, Turner served as a manufacturing engineer supervisor/industrial engineer, and more recently manufacturing engineering manager, for Plasan North America in Bennington, Vt. During his career, he also built his skill set at NSK Steering Systems America in Bennington, Vt.; as well as at J.S. McNamara and Utica Engineering Company in Shelby Township, Mich. Turner has a bachelor of science in engineering degree with a focus on mechanical engineering from Oakland University in Rochester, Michigan.

Ann Wedell has joined the Mack team as a quality engineer at the Company Headquarters in Arlington, Vt., providing support during new business development, as well as new and existing programs. A graduate of the University of Dayton, Wedell has a bachelor of chemical engineering degree. Prior to Mack, she gained quality and engineering experience as an intern at Alliant Tech Systems in Beavercreek, Ohio, and a process engineer with International Paper in Rome, Ga. Most recently, she served as a process engineer with Dedert Corporation in Homewood, Ill., where she worked closely with project management, performing various calculations and project specifications to ensure critical specs were met.

Ann Wedell has joined the Mack team as a quality engineer at the Company Headquarters in Arlington, Vt., providing support during new business development, as well as new and existing programs. A graduate of the University of Dayton, Wedell has a bachelor of chemical engineering degree. Prior to Mack, she gained quality and engineering experience as an intern at Alliant Tech Systems in Beavercreek, Ohio, and a process engineer with International Paper in Rome, Ga. Most recently, she served as a process engineer with Dedert Corporation in Homewood, Ill., where she worked closely with project management, performing various calculations and project specifications to ensure critical specs were met.

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

# # #

Contact: Larry Hovish

(802) 375-0772

larry.hovish@mack.com