BENNINGTON, VT—April 21, 2020—Mack Molding and Southwestern Vermont Health Care (SVHC) have partnered to develop an innovative alternative for Personal Protective Equipment for the health system. Similar to the rest of the country, southern Vermont has not been immune to the challenges of acquiring PPE during the COVID-19 crisis, and most specifically disposable masks. Through their collaboration, Mack and SVHC began investigating alternative mask options that could be modified since N95s masks and 7700 respirators are in high demand.

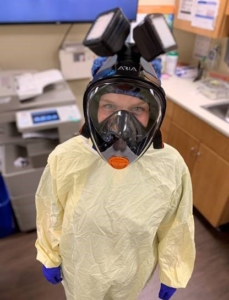

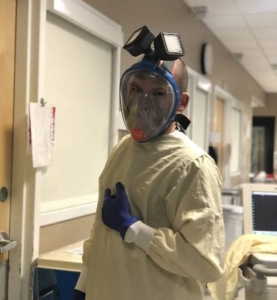

Christopher Darby, RN, CEN, Emergency Department Clinical Coordinator, using the mask in the SVMC Emergency Department.

The collaboration arose out of personal connections. Kevin Dailey, the vice president of Administration/CHRO at Southwestern Vermont Health Care (SVHC) had led human resources at Mack until 5 years ago. He knew the type of specialty plastics manufacturing and rapid product development Mack was capable of. When it was clear that PPE would likely run short, he gave his friends there a call. Realizing the extraordinary tight time-frame and regionally important challenge, Mack—a leading supplier of contract injection molded plastic parts to companies in a range of industries—called on Adam Lehman, president of their subsidiary, Woodbridge, Conn.,-based Synectic, to identify immediately available options that could be redesigned to function as a respirator. Lehman located a snorkeling mask that the Synectic design team could quickly re-engineer into Personal Protective Equipment (PPE).

“When I informed Synectic’s team about this project, they were ready and excited for the challenge,” said Jeff Somple, president at Mack headquarters in nearby Arlington, VT. “It was an opportunity for some groundbreaking innovation and to make a meaningful difference for our region’s front line healthcare workers.”

After only two weeks of design, testing, and manufacturing, Mack’s team at Synectic fabricated an attachment to a snorkeling scuba mask. The mask covers the entire face and denecessitates the use of disposable masks and shields. Their engineers removed the part that usually protrudes out of the water when snorkeling and replaced it with a new, custom-designed branched component equipped with cartridges containing P100 HEPA filters.

“Mack has always been a tremendous regional partner and an integral supporter of the health system for many years,” Dailey said. “As an essential manufacturer of health care products, I knew that they would want to help and came through with a brilliant solution for us.”

Each SVHC staff member is “fit tested” to ensure an adequate seal and assigned a mask. Each employee receives cleaning and storage guidelines, instructing how to disinfect and store their mask after each shift. The custom snorkeling branch modification and P100 HEPA filter casings can be easily removed for cleaning and screwed securely back in place. Before each use, staff conduct a positive and negative pressure test to ensure the masks are holding up for their protection. The fact that the air intake is above the wearer’s head improves the line of site and allows patients to see their physicians’ and nurses’ faces more clearly.

“Our priority is to ensure the safety of our staff while caring for patients during the pandemic,” said Shiela Boni, RN, MSN, a nursing director and PPE officer for SVHC. “The retrofitted scuba mask accomplishes this while decreasing our dependence on disposable masks.”

Unlike medically approved respirators, the scuba mask has been adapted to meet the filtration requirements of personal protective equipment (PPE). The risk assessment conducted by Mack’s design and SVHC showed that the mask fully seals around the face with silicone, reducing skin breakdown, and the N100 HEPA filters have a higher rate of filtration than the material in the traditional N95 masks. Less than three weeks after the initial request to Mack, their subsidiary Synectic delivered 500 scuba masks and 2,000 N100 HEPA filter casings to the hospital.

Thomas A. Dee, FACHE, SVHC’s president and CEO, expressed relief at having secured the adapted scuba masks to outfit those in the highest risk areas of the hospital. “This is a great example of how collaboration and innovation sustain us during challenging times,” Dee said. “Our gratitude for the hardworking teams at Mack and Synectic, who put many long hours into this project, cannot be overstated. This is another wonderful example of Mack’s continued support of SVHC.”

Additional photos of staff using the adapted scuba masks are available upon request.

About SVHC:

Southwestern Vermont Health Care (SVHC) is a comprehensive, preeminent, health care system providing exceptional, convenient, and affordable care to the communities of Bennington and Windham Counties of Vermont, eastern Rensselaer and Washington Counties of New York, and northern Berkshire County in Massachusetts. SVHC includes Southwestern Vermont Medical Center (SVMC), Southwestern Vermont Regional Cancer Center, the Centers for Living and Rehabilitation, and the SVHC Foundation. SVMC includes 25 primary and specialty care practices.

A COVID-19 information hotline is available for community members. The number, 802-440-8844, is answered 8 a.m. – 5 p.m. on weekdays. A recorded message provides the most frequently requested information. Telephone numbers and other COVID-19 information, including frequently asked questions and helpful resources, are available at svhealthcare.org/covid-19.

Southwestern Vermont Medical Center provides exceptional care without discriminating on the basis of an individual’s age, race, ethnicity, religion, culture, language, physical or mental disability, socioeconomic status, sex, sexual orientation, or gender identity or expression. Language assistance services, free of charge, are available at 1-800-367-9559.

About Mack Molding

Mack Molding is a leading custom plastics molder and supplier of contract manufacturing services. Mack specializes in plastics design, prototyping, molding, sheet metal fabrication, full-service machining and medical device manufacturing. Founded in 1920, Mack is a privately owned business that operates 11 facilities throughout the world. Don Kendall is CEO and chairman. For more information, go to www.mack.com.

Media Contacts:

| Ray Smith | Larry Hovish |

| Director of Marketing & Communications | Director of Communications |

| Southwestern Vermont Medical Center | Mack Molding Company |

| (802) 447-50003 | (802) 375-0772 |

| ray.smith@svhealthcare.org | larry.hovish@mack.com |