ETM: How to make lighter, stiffer, smoother parts

Making a thick-walled part with an internal foam structure isn’t new. For decades, the plastics industry has been using the structural foam and microcellular foam processes to produce skin-core-skin structures with foamed bubbles.

The result is a light, but stiff, part that can be produced with lower tonnage and few, if any, sink marks. The downside is a swirled surface, due to out-gassing trapped at the part/mold interface, which ultimately requires secondary painting for good cosmetics. Several approaches have been employed over the years to improve surface quality, including gas counter pressure, hot/cold mold cycling, expanding molds, Teflon film or other coatings, co-injection molding, vapor polishing, and so on.

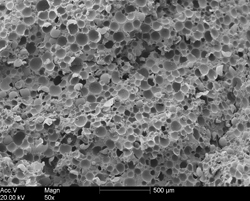

An ETM cell structure as viewed through a reflection electron microscope. Note: 500 µm = 0.5 mm.

A newer approach is expandable thermoplastic microspheres (ETM), commercially known as Expancel, which has been used for some time in the extrusion process but is only now finding its place in injection molding. ETMs are small spherical thermoplastic resin particles comprised of a virtually gas-proof polymer shell that encapsulates hydrocarbons as a blowing agent. The average diameter of the hollow spheres ranges from 6-45 µm. Fully expanded, the volume of the microspheres can increase more than 40 times.

The typical expansion temperatures range from 80º to 190ºC (176º to 374ºF). When heating the microspheres, the pressure of the gas inside the shell increases as the thermoplastic shell softens, resulting in a dramatic volumetric increase. Cooling stiffens the outer shell to its original state, leaving the light, expanded microspheres ready for use. Because little or no gas escapes from the microspheres, the surface quality of the molded part is dramatically improved.

The use of ETMs in injection molding enables part weight reduction while maintaining dimensional stability. Compared with structural foam or microcellular injection molding technology, the expandable microspheres improve surface quality substantially, reducing or eliminating the need for secondary operations. This is accomplished by controlling the size, density and skin layer thickness of the microstructure with the amount of ETM used.

During recent samplings, we have experienced base density reductions up to 50% in ETM-molded parts. This density reduction matches that found in microcellular foam molded parts, and certainly exceeds the 5-25% average density reduction typically achieved with structural foam molding. Part size and wall thickness, as well as the ratio of base resin to ETM, are determining factors in the process and must be optimized on a part-by-part basis.

The above post was written by Michael Hansen, PhD, Senior Technical Development Engineer, MackMedical/Mack Molding

michael.hansen@mack.com

Final Storm Update — ‘Irene’ Emergency Over!

As we look at the results of Tropical Storm Irene in the rear view mirror, we’d like to pause for a moment to thank our customers for their understanding and support. Even though trucks couldn’t initially get to our Cavendish plant, there was minimal disruption to customer commitments, a testament to both customer flexibility and the extremely hard work of our Cavendish employees.

Out of emergency mode and into the rebuilding phase, we’re replacing floors and painting walls. By Christmas, you’ll be able to tour a ‘new and improved’ Cavendish, with no hint of the flood damage left in Irene’s wake.

Most importantly, we’re fully operational. In fact, as I write this, the plant is undergoing its normal end-of-quarter inventory, which will clearly illustrate the status of all purchased parts.

This will be our last blog about the Cavendish flood, and I hope to NEVER have to write another one! Before closing, though, I want to applaud our staff once again, both in Cavendish and from the other plants that pitched in – they have shown an incredible work ethic and devotion to Mack Molding, for which we are all extremely grateful!

Look for news on a different topic in our next blog, and be sure to sign up for the RSS Feed to be automatically notified when updates are posted.

Jeff Somple

President, Northern Operations

Storm Update #3 — Production and Recovery

Mack’s Cavendish plant continues to operate at full strength. In fact, we have added temporary staff to help with the critical task of purchased part inventory, the area of the plant that suffered the most water damage. We have established an inventory triage area where purchased parts are being sorted, inspected and evaluated. We have set up multiple cleaning stations for parts that can be salvaged, as well as a temporary warehouse for damaged goods that need to be dispositioned.

Additional resources from Purchasing, Quality and Sales/Engineering have been on-site to assist with decision-making and customer communication. The extra efforts from the Cavendish workforce have been incredible!

The molding machines and auxiliary equipment are in very good shape and focused on production. The finishing department is split between production and inventory analysis, as described above.

While the flooding eroded some of the rear parking lot, we have had over 50 dump trucks of fill delivered to date, and expect to add about 30 more. This work should be completed by the end of next week. Once finished, we can repair the foundation for the resin silo.

As mentioned in an earlier post, our Business Continuity/Emergency Response Plan was put into action immediately. Much of the plan worked exactly as it should. While we didn’t anticipate some of the challenges posed by hurricanes and flooding, rare events in Vermont, we’re working to improve the plan to address even these most extreme situations. Opportunities for improvement should never go to waste!

As we get new information regarding Cavendish, we will share it here. Sign up for the RSS Feed to be automatically notified when updates are posted.

Jeff Somple

President, Northern Operations

Storm Update #2 — Cavendish Up & Running!

Incredible effort throughout the Labor Day weekend from Mack crews, who continued to work on both production and cleanup — great work! The town was also busy, cleaning up area roads and installing a new water line to the plant. We now have water, which will allow production and cleanup to progress faster and easier. Crews also installed a new transformer Saturday morning, so we now have full electrical service to the entire building. While there is still a lot of cleanup work to do, the plant is now fully functional.

As we get new information regarding Cavendish, we will share it here. Sign up for the RSS Feed to be automatically notified when updates are posted.

Jeff Somple

President, Northern Operations

Storm Status

Unless you’ve had your nose stuck in a book for the last week, you’ve no doubt seen some of the devastation Irene dealt to the state of Vermont. While ‘hurricanes’ and ‘Vermont’ are typically not found in the same sentence, this storm was anything but typical! Our thoughts go out to all those affected, especially our fellow Vermonters.

From Mack’s perspective, we were exceptionally lucky! Two of our three manufacturing plants – Headquarters and Arlington – are fully operational with no storm-related damage. Our Cavendish facility did incur some water damage, so we are following our Business Continuity/Emergency Response Plan to assess customer impact, if any. Should we determine that a mold needs to run to meet customer needs, our other plants stand ready to receive and run tools.

Currently, the water has receded and employees are able to get to the plant to help with cleanup. Already, it is beginning to look like Cavendish again! Power has been restored, and town crews are hard at work to restore water to the facility. No molds were damaged, and inventory appears to be in good shape. We expect to begin shipping and receiving tomorrow.

As we get new information regarding Cavendish, we will share it here, so please check back often.

Best wishes,

Jeff Somple

President, Northern Operations